Arbor SNOWBAORDS CELEBRATES ITS 25TH ANNIVERSARY

In November 2020 Arbor Snowboards celebrated its 25th anniversary. This makes Arbor one of the oldest brands on the snowboard market. Reason enough to take a closer look at the brand from Venice Beach in California.

Los Angeles, Early 90s

The two friends Bob Carlson and Chris Jensen, who grew up in Venice Beach and dedicated their childhood and youth to surfing and skateboarding, or sidewalk surfing as it was often called at the beginning of the skate era, have devoted themselves with increasing enthusiasm to the relatively young sport of snowboarding in recent years and spend every spare minute on the mountain. What both of them noticed early on is the fact that environmental protection has little attention in the action sports scene at that time. To be flown to the summit by a helicopter was the dream of every ambitious hobby snowboarder and the stars of the scene were celebrated for exploring new terrain in the remotest corners of the world. It soon became clear to them that this is in great contrast to their own convictions.

Arbor SNOWBAORDS – creating a sustainable boardsport brand matures

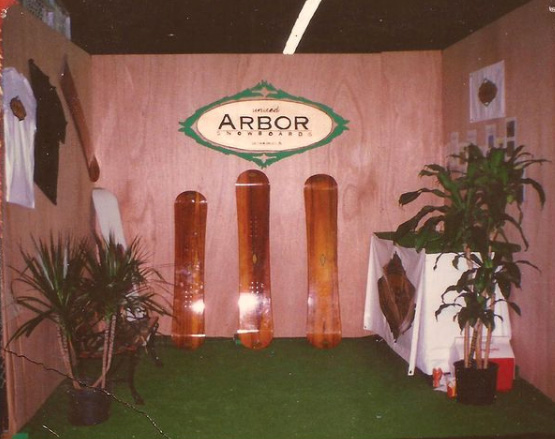

Because after all, it is the nature that enables them to pursue their great passion, board sports in water and snow, and therefore they feel it is particularly worth protecting. Both were convinced that it can be done better and so the idea of creating a sustainable boardsports brand matures. Initially sceptical, Bob Carlson is completely convinced when Chris Jensen presents him the first prototype of a snowboard with a wooden topsheet in 1994, in which the wooden topsheet also has a structural function, namely the reduction of the glass fibre mats used. Both soon realised that they wanted to devote themselves to this idea with full commitment. This is how the Arbor brand was created in 1995. The first model, the Arbor Element, still one of the cornerstones of the collection, was presented at the North American sporting goods fair SIA.

Arbor Booth – SIA 1995

Arbor SNOWBAORDS -25 Years later

Arbor is an established player in the snowboard world and has grown into a global brand with a multinational team that produces not only snowboards but also skateboards and apparel in a sustainable way. As pioneers of a environmentally conscious snowboard production, the company has constantly evolved and strives every day to push the limits of what is possible in the area of manufacturing its own products in the most environmentally friendly way possible. This is how the snowboard production has ended up in the Arab Emirate of Dubai, in the still quite young and extremely modern SWS factory. What sounds extremely strange and not exactly sustainable to Europeans at a first glance, namely moving production to an Arab Emirate in the desert after years of pride in producing in an Austrian factory, makes a lot of sense when taking a closer look.

The factory in the Arab Emirate of Dubai, which was built at the beginning of 2010, is one of the most modern production facilities in the boardsports sector currently available. The factory manager John Colvin, who already had a wealth of experience in snowboard production at that time, had an empty factory hall at his disposal, which he and his team could design according to their own ideas. The result is a production facility that not only has excellent filter systems and operates in a closed system and completely reuses the resources used, such as water, but since 2020 has also been fed 100% from solar energy. This, in combination with the globally very central location, which helps to minimise worldwide transport distances, puts a production facility in the middle of the desert in a completely different light and explains why this location was chosen at that time.

Part of the soplar system SWS – Dubai

Arbor also remains a pioneer in terms of the materials used in its products. The initial idea of using the renewable raw material wood as a structural component of snowboard construction and minimising the use of petroleum-based materials such as plastics and fibreglass is still pursued today. This not only gives the Arbor snowboards their characteristic look, but is also an elementary part of the sustainable production method. In addition to the use of FSC®-certified woods for the cores and powerply topsheets of the snowboards, numerous other materials made from sustainable or recycled materials are now also used. For example, the snowboards in the line, which do not have a wooden powerply topsheet, have been switched to a non-petroleum-based so-called bioplastic, which is obtained from castor beans.

In addition, resins and other composites made from natural, non-petroleum-based resources are now used throughout, only recycled stainless steel is used for the edges, recycled sidewalls are used wherever possible, the materials used, such as for the base, are consumed with technologies such as flip-flop bases that leave as little residual waste as possible, and only wax from non-fluorine-based natural sources is used for fine-tuning the snowboards.

Earn your Turn – Focus Category Splitboard

But the efforts to make snowboarding, which is not a very sustainable sport per se, as environmentally friendly as possible, do not stop at Arbor during production. Also in the area of product development and the composition of the line, they try to emphasize the overall orientation of the brand. Together with team riders who are also committed to sustainability, such as Marie-France Roy or the grand seigneur of backcountry snowboarding, Bryan Iguchi, the splitboard line has been continuously expanded and improved in recent years, as the company is convinced that climbing the peaks on one’s own energy is a good idea and can generally contribute to making snowboarding less harmful to the environment. In addition, the Splitboard offers many other advantages, such as the fact that it also gives the normal snowboarder the possibility to explore the terrain away from the areas and to draw first lines, even days after the last snowfall.

This and the fact that it is a qualitatively completely different experience if you proceed according to the principle “Earn your Turn” and thus earn the powder run yourself, make the split board segment a real focus category at Arbor, which they have continuously expanded in the past years and will continue to expand in the future. While a few years ago there was only one splitboard in the programme, the Abacus, the sector has now grown to 4 models (Bryan Iguchi Pro Splitboard, Coda Rocker and Camber Splitboard, as well as the Swoon Rocker Splitboard) and is to be supplemented by 3 further models in the coming years. Also with the field of technology we try to develop constantly. This year, for example, the Coda Camber Splitboard is the first splitboard that does without the Uprise Fenders known from the Camber System. The so-called 4-point no fender design offers an extremely good edge hold in ascent and descent and an extremely direct handling, even in steep or icy passages. For the future, Arbor is also planning to rely more on the Rise Above Plastics (R.A.P.) technology known from the Solid models, which completely dispenses with the use of bio-plastic in the topsheet and instead pre-seals the wood and presses it directly onto the core. This in turn leads to a weight reduction and the times when snow sticks to the topsheets are a thing of the past.

As you can see, the Californian brand, which was the first snowboard brand in the world to adopt a sustainable approach, is not standing still and has been striving to expand and raise the standards of sustainable and future-proof production from the day it was founded until today. At a time when climate change is just one of the many environmental problems facing the world, it is certainly desirable that a brand like Arbor continues to push the boundaries of sustainable production and inspire others to follow suit. In this spirit, to the next 25 years!

Find more related articles about snowboarding and splitboarding:

→ Everything about Down Jackets

Cover foto:

Rider: Mario Wanger

Photographer: Philipp Huber